Reinforced Concrete Design Chapter 8 (cont..1) Layout of main bars in a continuous one way slab

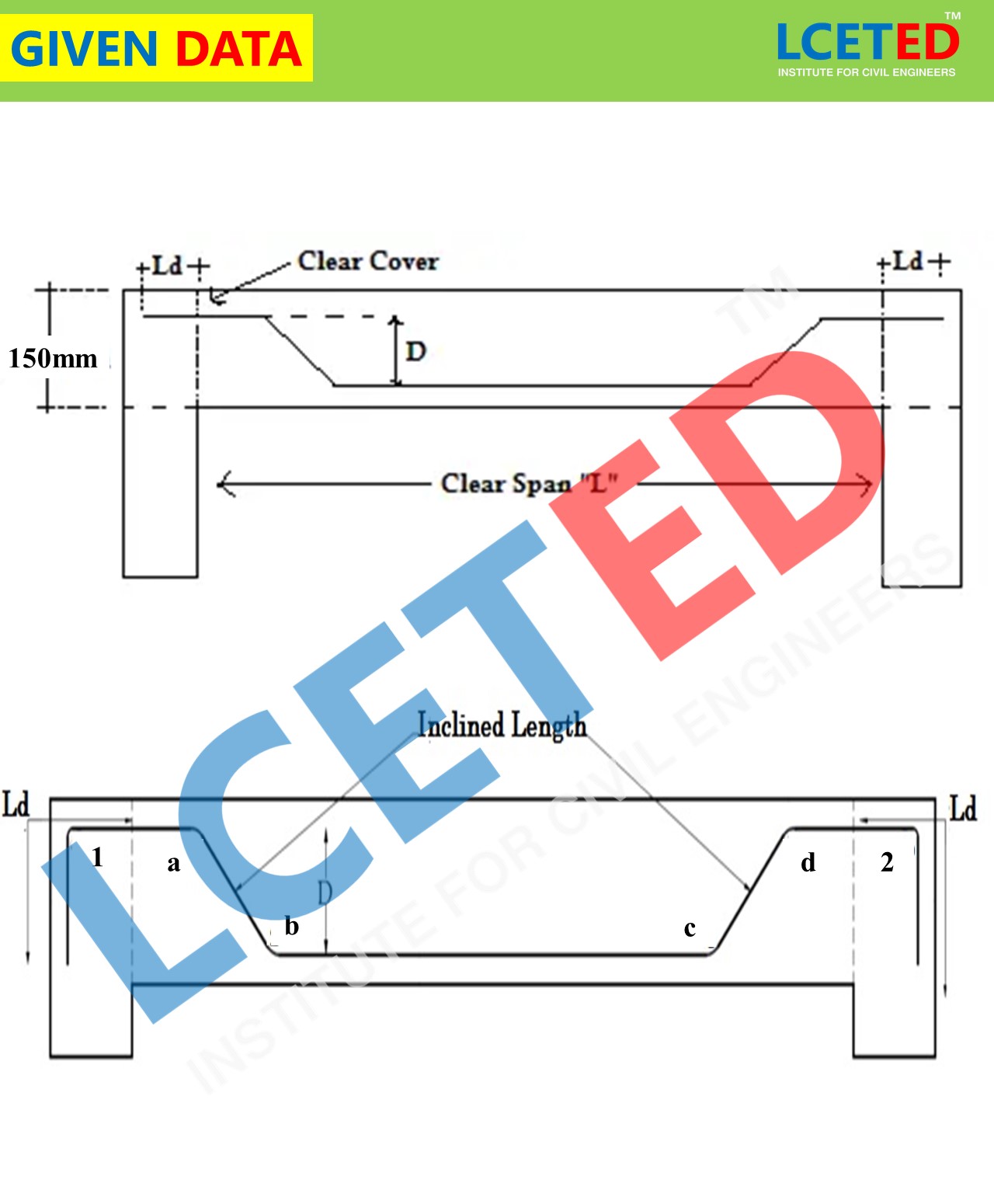

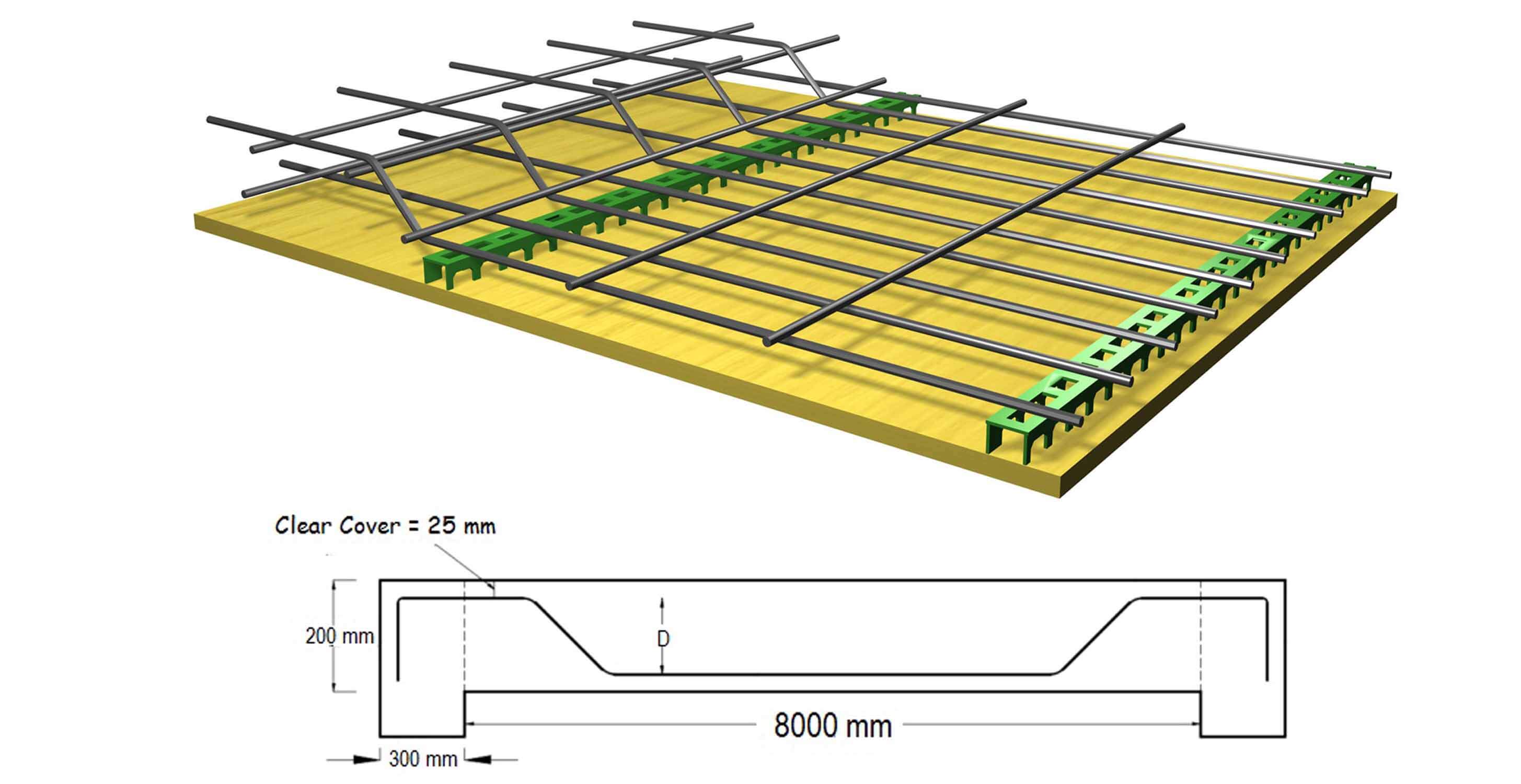

D = Height of the bending bar. In the above formula, all values are known except 'D'. So we need to find out the value of "D". Cutting Length = Clear Span of Slab + (2 x Ld) + (2 x 0.42D) - (1d x 4) - (2d x 2) ∴ Cutting Length = 8980 mm or 8.98 m. So for the above dimension, you need to cut the main bars 8.98 m in length.

Why Crank Bars Provide in Beam Bent Up Bars in Beam YouTube

Issue: Appears on pages (s): 249-266. Keywords: bars; beams (supports); bent-up bars; crack width and spacing; cracking (fracturing); reinforced concrete; reinforcing concrete; reinforcing steels; shear strength; tests. DOI: 10.14359/17287. Date: 1/1/1974. Abstract: The paper describes the results of a series of tests of beams reinforced with.

What Are The Reasons To Use cranked Or Bend Up Bars In slabs And Shallow Beams? Engineering

A Bar Bending Schedule (BBS) is a document that provides the proper cutting length, bending length, and the total quantity of steel bars required for a particular construction. It is presented in a tabular form for better understanding. A bar bending schedule is prepared for each structural unit such as beam, column, slab, footing, etc.

Bent up bar Column on beam Crank bars Green House Construction YouTube

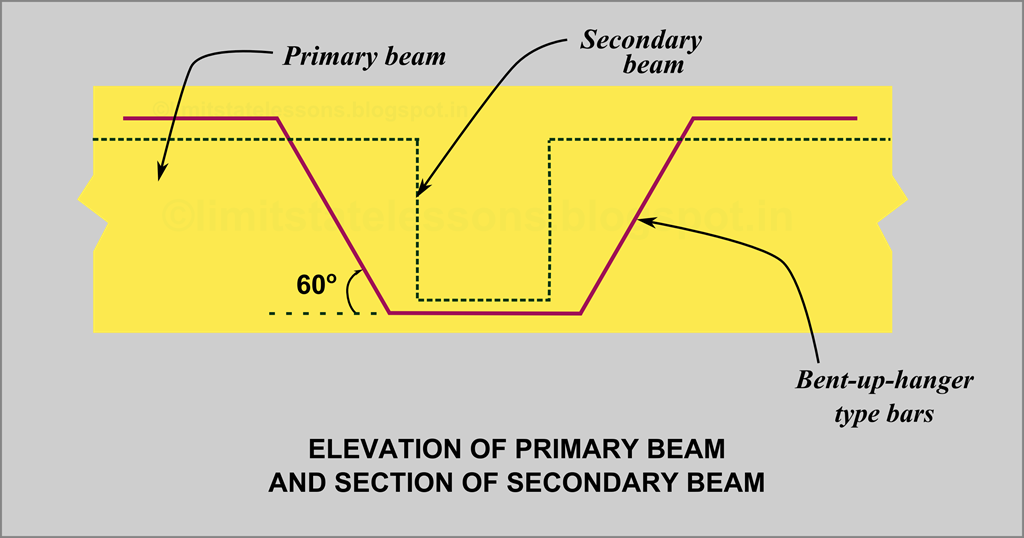

Using bent-up bars as shear reinforcement was state of the art in reinforced concrete (RC) construction until the 1970s. Since the approach to shear reinforcement design has changed since then, the structural assessment according of structural members to current structural codes often yield insufficient theoretical shear capacities.

Civil Engineering Information related with Crank bar in RCC Slab Bent Up bar in Slab YouTube

bent-up bars or both. 9,10,11,12 When bent-up bars are used as sole web reinforcement their spacing measured along the axis of the beam is prescribed by the buildings codes but these codes did not

Why Bent Up Bars are Not used in Beams These days l Bent Up Bars vs Straight Bars YouTube

The shear effectiveness of bent-up bars depends greatly on the shear span to effective depth ratio, the angle of inclination and its position. It is recommended that current code provisions should.

Reinforced Concrete Design Chapter 13 (cont..15) Critical sections for Shear design

6 June 2022 by Omotoriogun Victor [UPDATED] Design for Shear Using Bent-up Bars Every reinforced concrete element subjected to flexure is always accompanied by a shear force. This is a force that results in diagonal tension in concrete, consequently leading to failure via the formation of cracks.

Why Crank Bars / Bentup Bars are Provided in Slabs/Beams

Abstract and Figures. During the second half of the last century it was common in Europe to use bent-up bars of the longitudinal flexural reinforcement near the support of one-way slab bridges to.

KNOW HOW TO CALCULATE THE CUTTING LENGTH OF BENT UP BARS lceted LCETED INSTITUTE FOR CIVIL

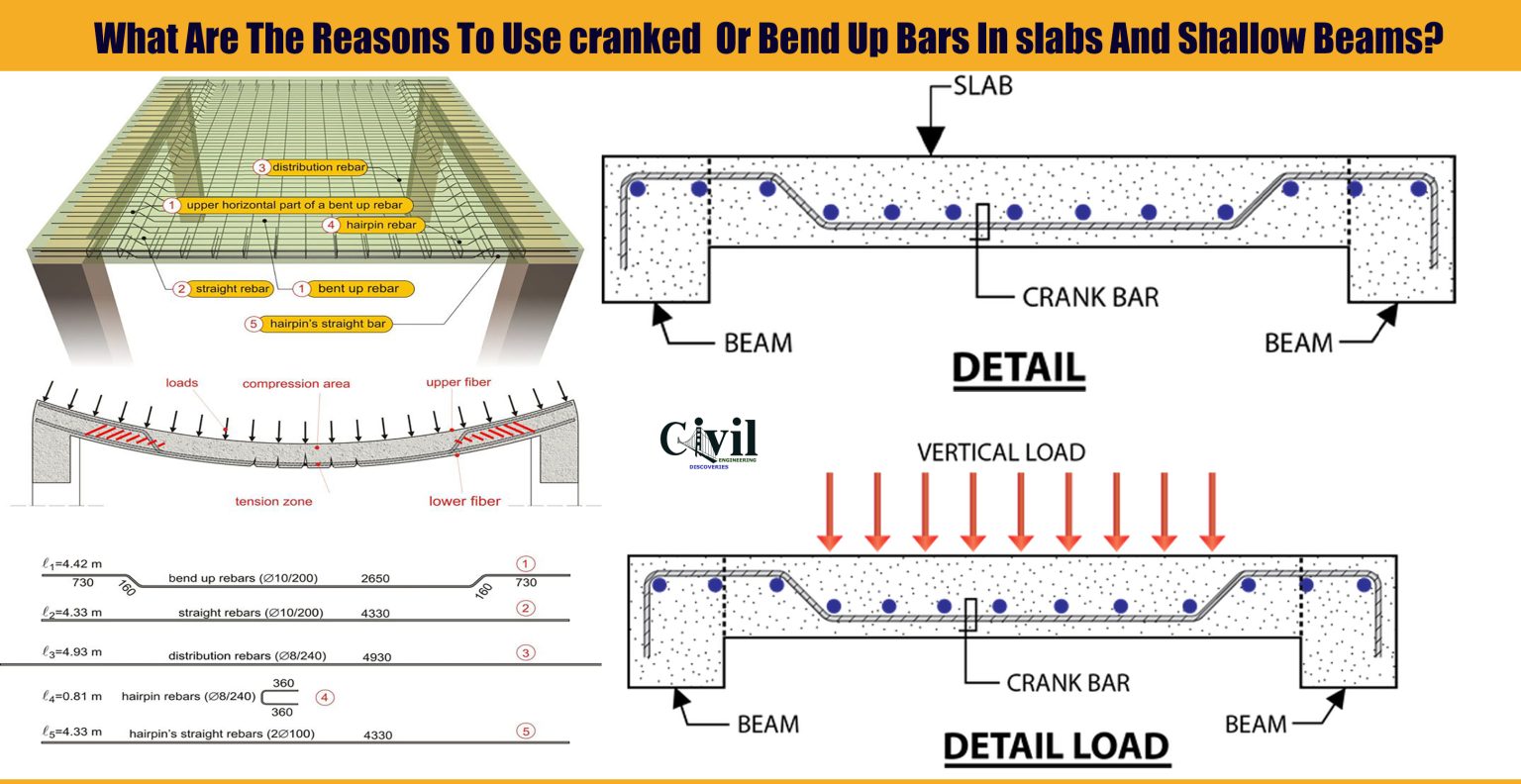

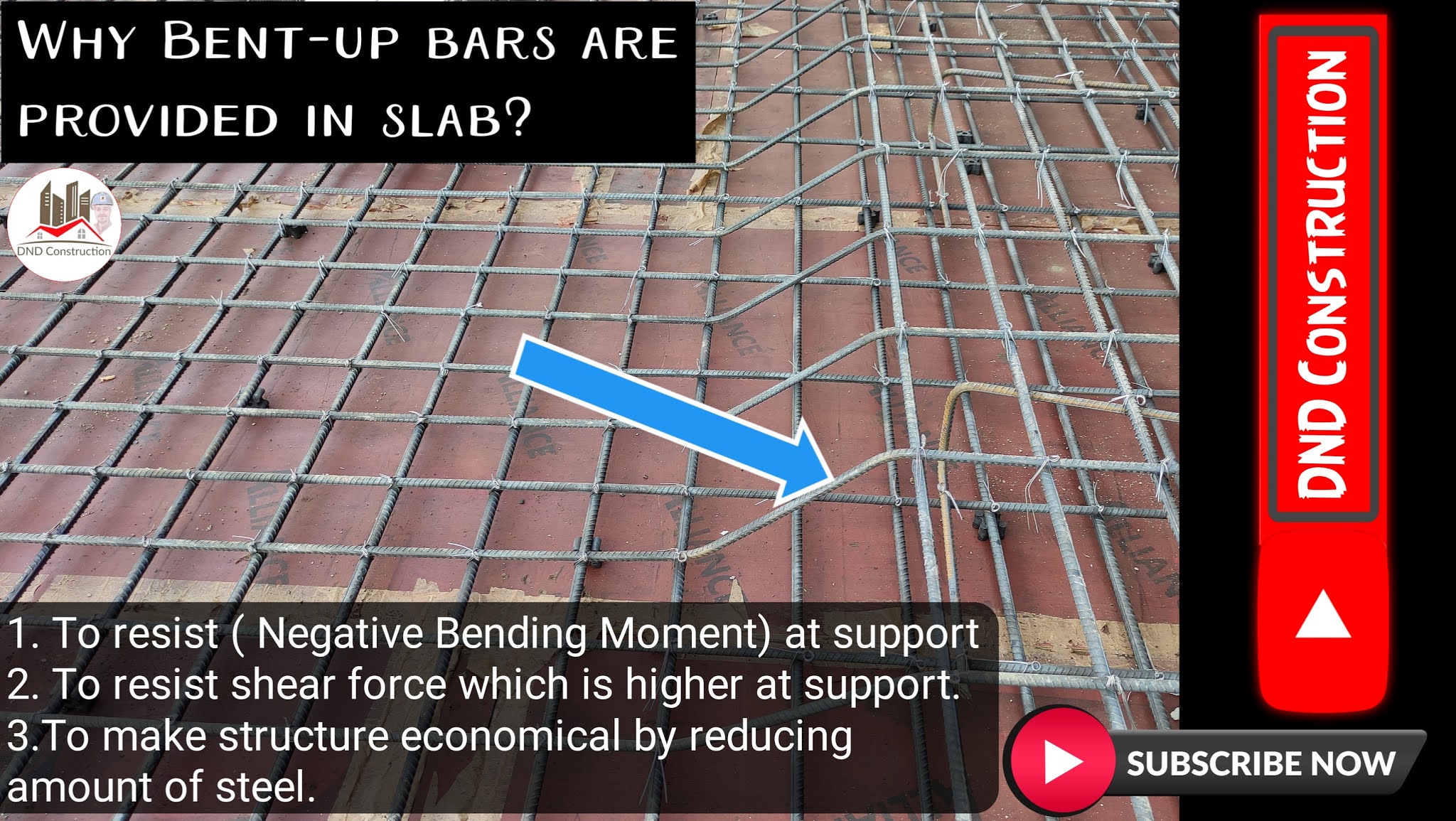

The uses of bent up bars are as follows: It helps to resist bending moments. It helps to withstand shear force (i.e. shear force maximum at support) It reduces the whole weight of the reinforcement bars required in the slab. It helps in reducing the cost of the project. It prevents failure of the slab due to SF.

KNOW HOW TO CALCULATE THE CUTTING LENGTH OF BENT UP BARS lceted LCETED INSTITUTE FOR CIVIL

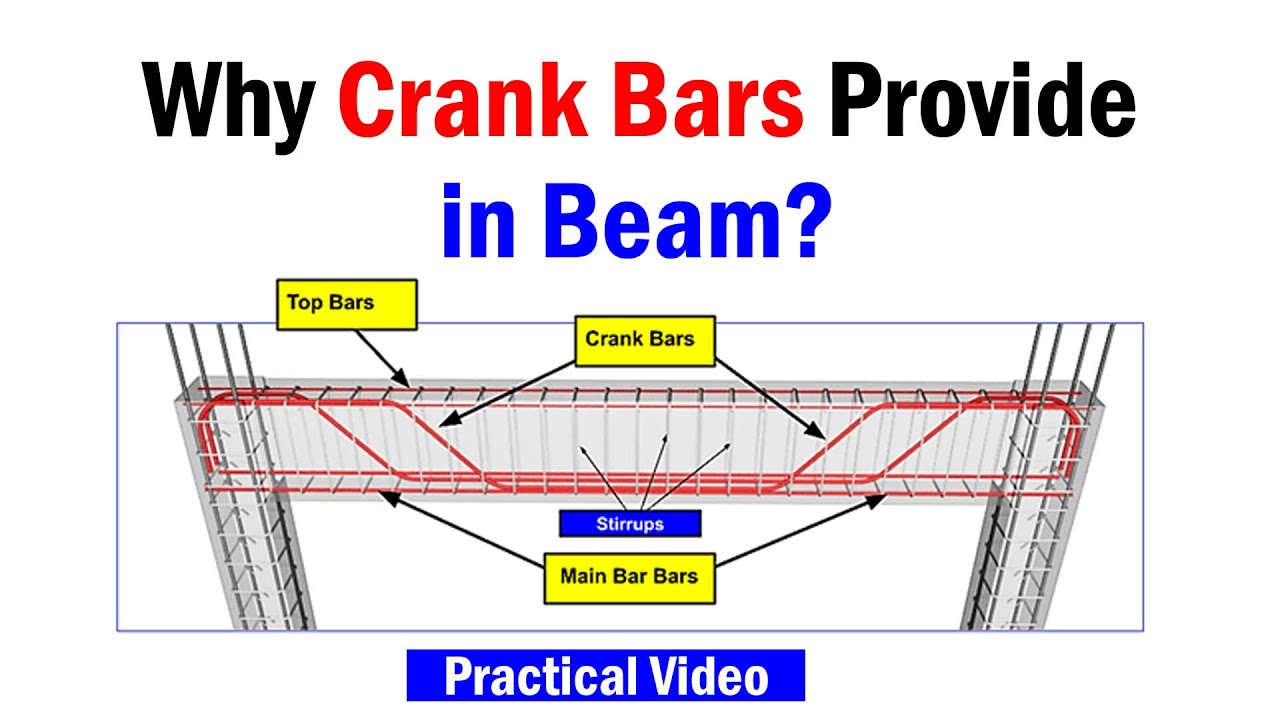

Crank bar also called as bent up bar used to resist both positive and negative bending moments. This video shows the importance of crank bar in beam and slab. Crank bar also called as bent up.

Why Crank Bars / Bentup Bars are Provided in Slabs/Beams

To economize the design of a flexural member, the tensile bars are curtailed at the section beyond which it is no longer required to resist flexure (bending) given that the remaining reinforcement of the flexural member will be able to resist the bending moment and shear created on the flexural member safely.

Calculate Cutting Length Of Bent Up Bar In Slab Engineering Discoveries

Bent-up bars play a crucial role in reinforcing slabs and enhancing their structural integrity. To summarize the key reasons behind their usage: Increased Shear Strength: Bent-up bars extending into the slab enhance its ability to resist shear forces and cracking, making it more robust and capable of withstanding loads.

Why Crank Bars / Bentup Bars are Provided in Slabs/Beams

The crank bars or bent up bar are very important in R.C.C beam or slabs construction because without countering the Hogging (Negative moment) the structure will fail or the strength of the structure will reduce. The hogging bending moment will develop at the supports of the slabs and beams. To resist Hogging (Negative Bending Moment) at supports.

Why Crank Bars or Bentup Bars are Provided in Slabs Civil Snapshot

The crank bar 1. Helps in resisting bending moments. 2. Helps to withstand shear force i.e. maximum at the support. 3. Reduces the overall weight of reinforcement bars required in the slab. 4. Helps in reducing project costs. 5. Prevents the failure of the slab due to shear force. 3. Why do we provide alternative crank bars in slab reinforcement?

Steel Crossing in RCC Slab Bent Up Bar in RCC Slab RCC Slab YouTube

Bent-up bars were extensively used as shear reinforcement in beams and slabs from the first R/C developments up to the 1970's. Their use was justified by the fact that they allowed enhanced development of the tensile reinforcement at the same time they acted as shear reinforcement.

Why Crank Bars Or Bent Up Bars Are Provided In RCC Slab YouTube

Bent up bars or Cranked Bars | Why Bent up bars or Cranked Bars are Used in slab and beams In this short video lecture, we will try to answer the following i.